In today's manufacturing industry, data has become a powerful catalyst for achieving revenue growth and improving profit margins. The utilization of data-driven strategies has transformed the way manufacturing companies operate, enabling them to make more informed decisions, enhance efficiency, and reduce costs. The following is a comprehensive exploration of how data is harnessed to achieve revenue and margin growth in manufacturing:

- Production Efficiency:

Data analytics plays a pivotal role in optimizing the manufacturing process. Sensors and IoT devices collect real-time data on equipment performance, production rates, and quality control metrics. This data helps manufacturers identify bottlenecks, minimize downtime, and enhance overall production efficiency. By streamlining operations, manufacturers can increase output while minimizing resource utilization, thereby boosting revenue and margins.

- Predictive Maintenance:

Data from sensors and machinery are used to develop predictive maintenance models. These models analyze data patterns to forecast when equipment is likely to fail. By conducting maintenance preemptively, manufacturers avoid costly unplanned downtime and emergency repairs. This not only reduces maintenance expenses but also ensures continuous production, contributing to revenue growth.

- Quality Control:

Data analytics is vital in maintaining product quality. Real-time data monitoring at various stages of the production process helps detect deviations from quality standards. This proactive approach minimizes the production of defective products, reducing the costs associated with recalls and warranty claims, thus preserving profit margins.

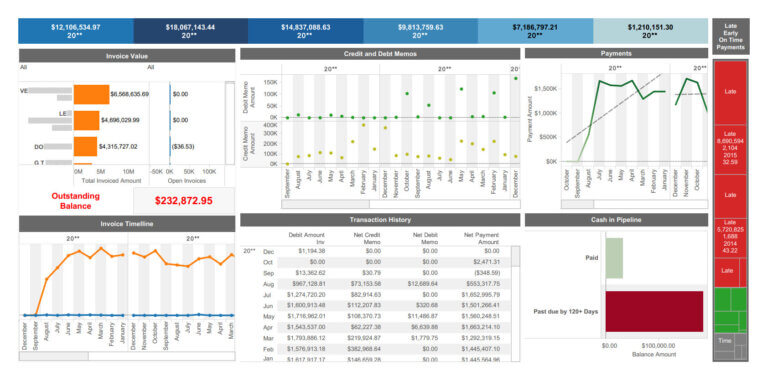

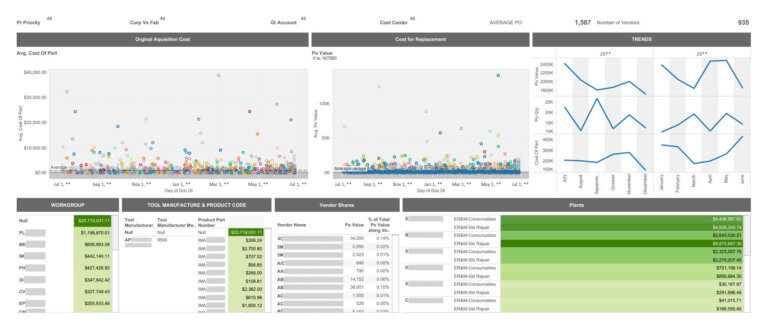

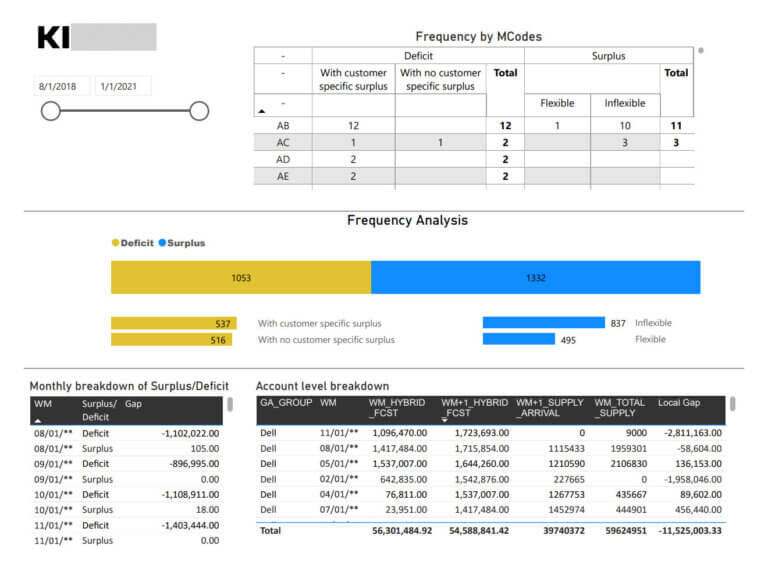

- Inventory Optimization:

Accurate demand forecasting and inventory management are essential for cost control and revenue growth. Data-driven analytics utilize historical sales data, market trends, and customer insights to forecast demand more accurately. This enables manufacturers to maintain optimal inventory levels, reducing carrying costs and minimizing the risk of overstocking or stockouts.

- Supply Chain Efficiency:

Efficient supply chain management relies on data-driven decisions. Real-time tracking of shipments, demand signals, and supplier performance data improves visibility across the supply chain. This transparency helps manufacturers make informed decisions, negotiate favorable terms with suppliers, and minimize costs associated with transportation and inventory management.

- Product Development:

Data-driven insights guide product development efforts. Manufacturers use customer feedback, market research, and consumer behavior data to tailor products to meet specific market demands. This minimizes the risk of launching unsuccessful products, contributing to revenue growth and preserving profit margins.

- Energy Efficiency:

Manufacturing facilities are significant energy consumers. Data analytics can identify energy usage patterns and inefficiencies, enabling manufacturers to implement energy-saving measures. Reduced energy consumption not only lowers operational costs but also aligns with sustainability goals, which can enhance brand reputation and revenue potential.

- Strategic Decision-Making:

Data-driven insights empower manufacturers to make strategic decisions with greater precision. By analyzing market trends, competitor performance, and internal operational data, companies can identify growth opportunities, enter new markets, or diversify their product portfolios strategically. This not only drives revenue growth but also improves profit margins.

In summary, data has become a cornerstone of modern manufacturing, offering a multitude of opportunities to improve efficiency, reduce costs, and drive revenue and profit margin growth. The ability to collect, analyze, and act upon data is crucial for manufacturers looking to stay competitive in an increasingly data-driven business environment. Those who harness data effectively can not only enhance their bottom line but also adapt more agilely to changing market dynamics and customer preferences, securing their long-term success in the manufacturing industry.